Learn How It Works

Pump Jack & Tank Battery 1:15

Learn more about the equipment used to produce and store crude oil from an active well.

CO2 Enhanced Oil Recovery 4:18

A type of tertiary oil recovery that can recover even more oil from these existing wells and reservoirs. In CO2 EOR, carbon dioxide is pumped into the oil-bearing rock formation to recover even more oil. CO2 EOR has the potential to recover an additional 15% to 20% of the original oil.

Oil Well Lifecycle 19:33

Learn about the entire process of oil well prospecting, geology, drilling, completion, production and plugging

Intro to Well Logging 8:18

Also known as borehole logging, this is the practice of making a detailed record of the geologic formations penetrated by a borehole. Check out this animation to learn more!

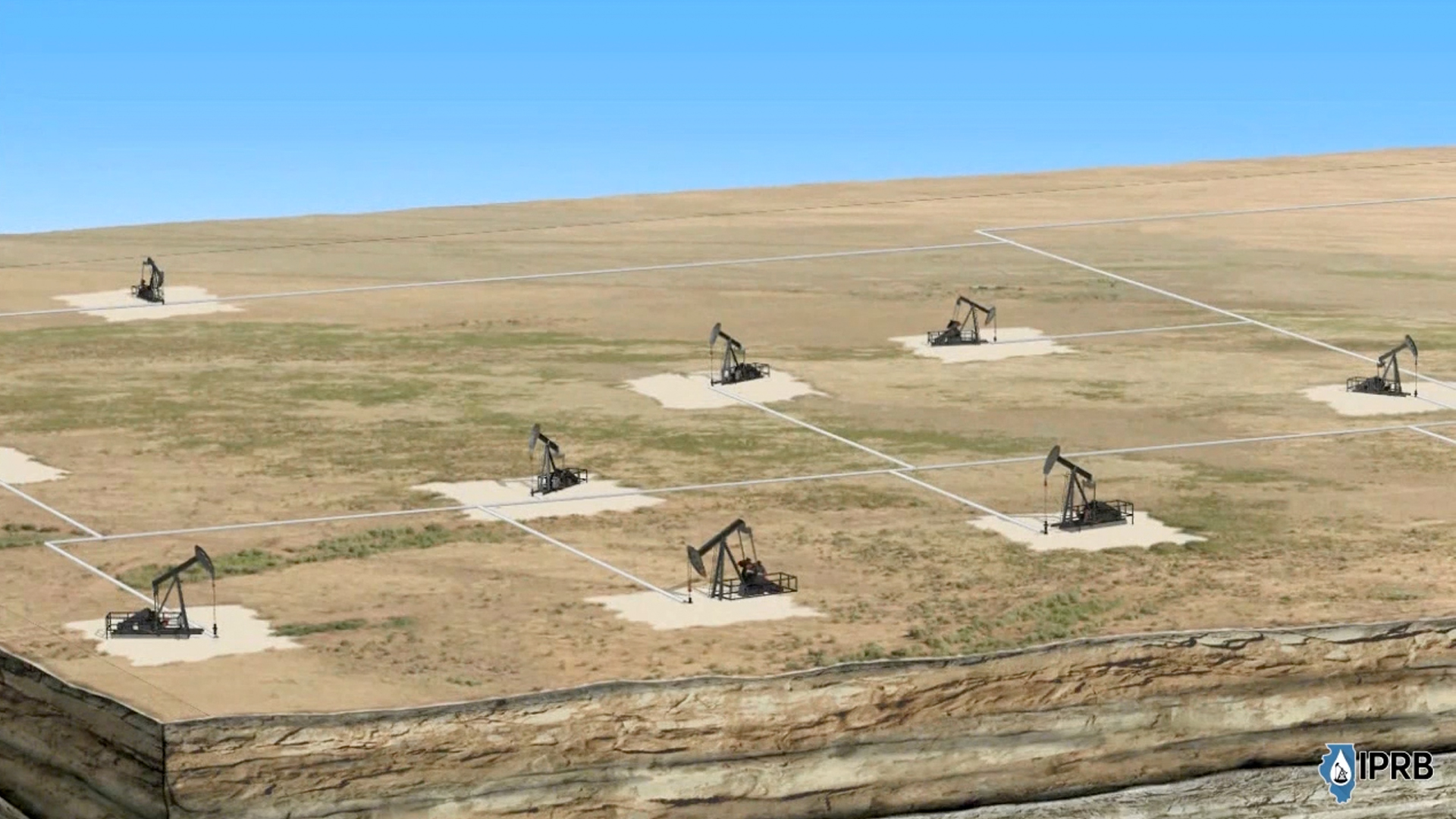

Waterflood 2:36

A secondary recovery method in which water is injected into a reservoir formation to displace residual oil. The water from injection wells physically sweeps the displaced oil to adjacent production wells. A typical waterflood includes four injection wells drilled in a square pattern with the production well in the center. Water from the injection wells moves through the formation, forcing oil toward the production well. Check out this animation to learn more!

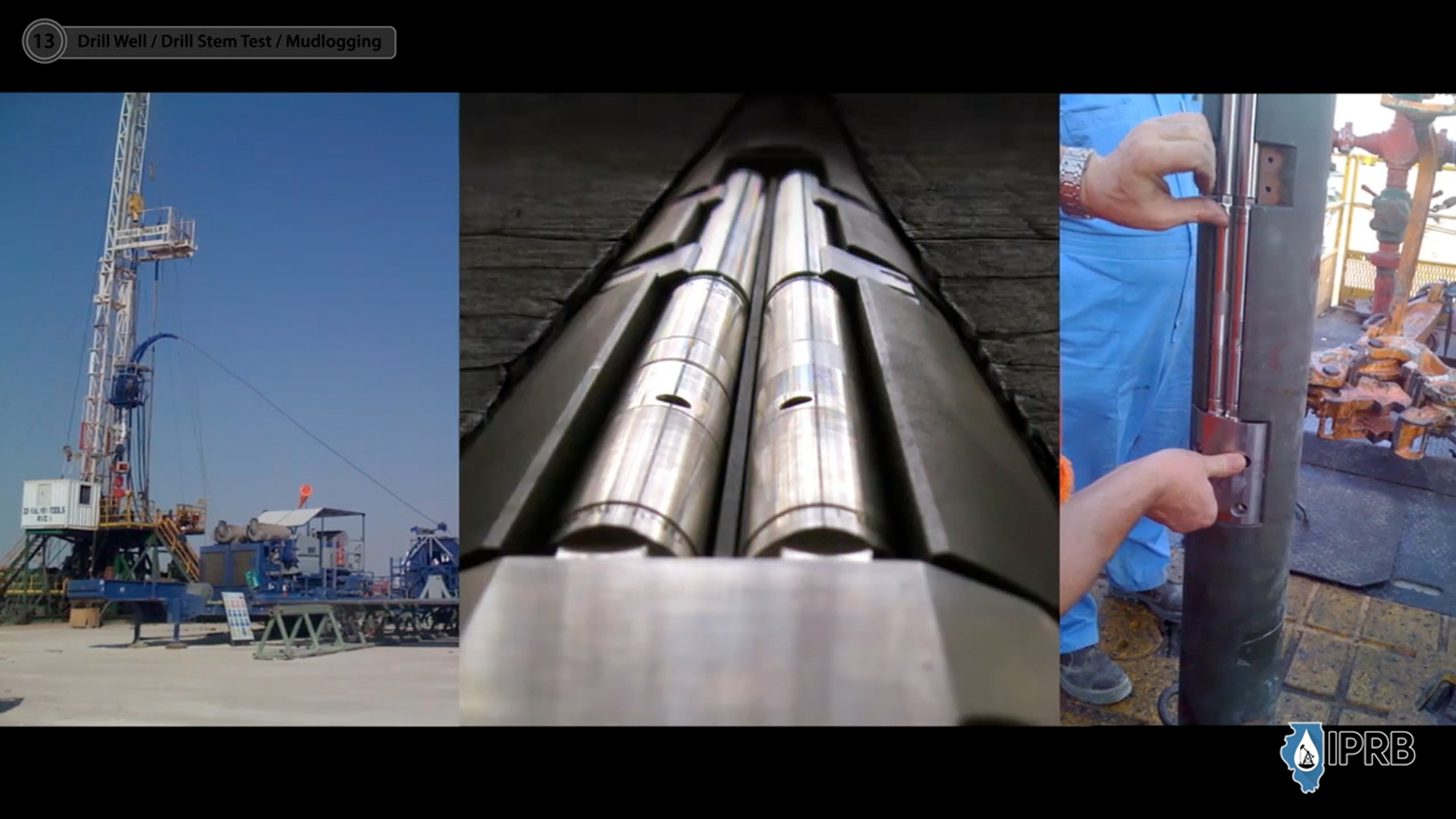

Drill Stem Testing 1:29

A drill stem test (DST) is a temporary well completion that is designed to determine the productivity and fluid properties prior to completion of the well. Check out this animation to learn more!

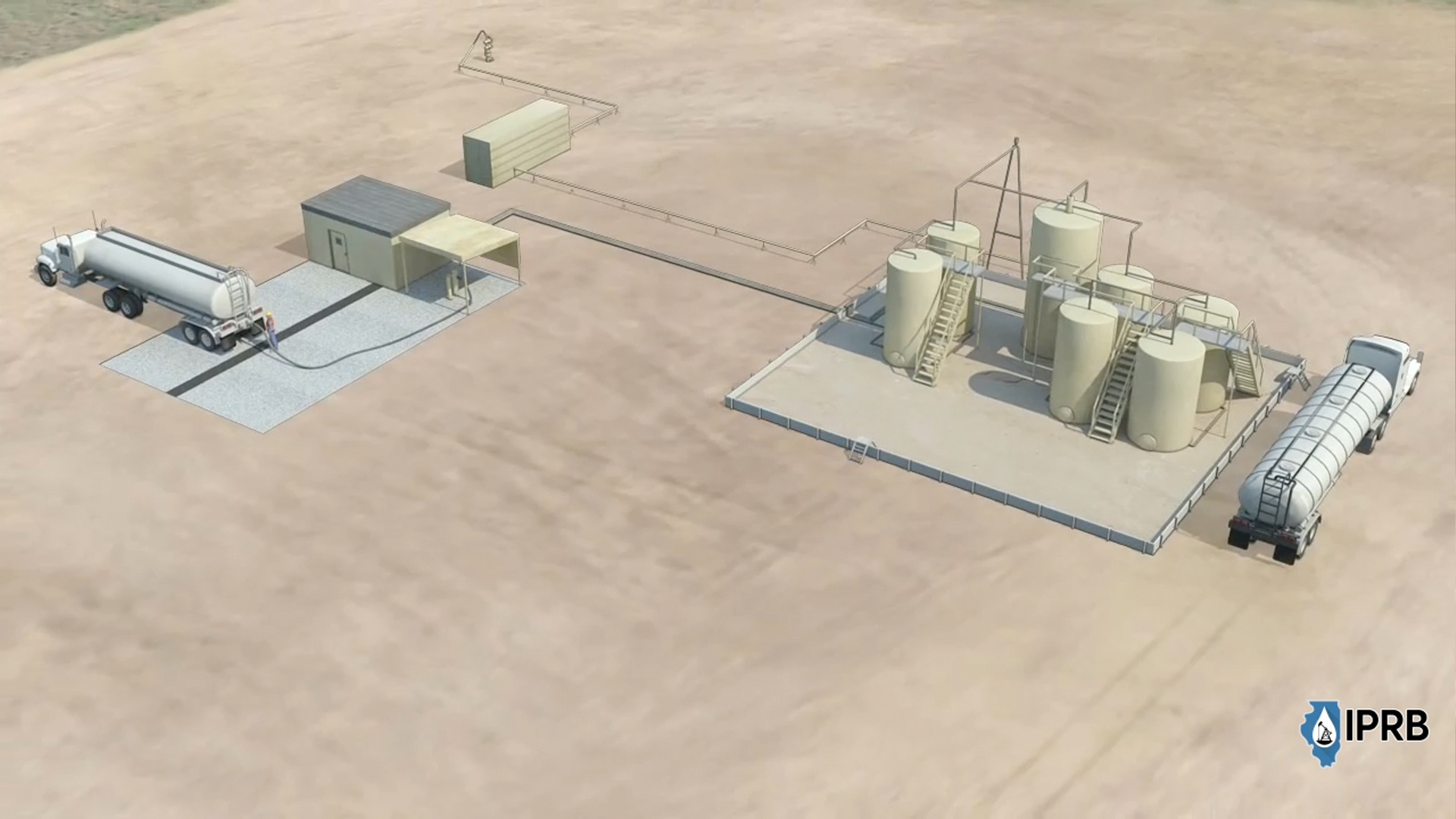

Salt Water Disposal Well 7:07

Did you know that underground deposits of oil and natural gas also typically contain large volumes of water? Why? Because millions of years ago, oil and gas producing regions were covered by oceans. Over time, marine life from this ocean collected along with oceanic saltwater, forming deposits of oil and natural gas along with brine (saltwater) in ancient geologic formations. Thus, when oil or natural gas is produced, salty water is typically produced alongside it, which is known as “produced water.” Often times, it must be injected into wastewater disposal wells, which are drilled several thousand feet below the surface. The wastewater is deposited into deep geologic structures, many of which have trapped brine for millions of years. These structures are often a mile or more below underground drinking water sources, separated by billions of tons of impenetrable rock. Oil and gas injection/disposal is an extensively regulated practice in Illinois and throughout the United States, and properly constructed injection/disposal wells do not pose a credible risk of water contamination and a number of regulatory safeguards are in place to protect groundwater. In fact, one of the main purposes of injection/disposal wells is actually to reduce the risk of water contamination, be it at the surface or underground. As the U.S. Environmental Protection Agency notes: “By injecting the brine deep underground, Class II (injection/disposal) wells prevent surface contamination of soil and water.” Here in Illinois — where the Illinois Department of Natural Resources Division of Oil and Gas (DOG) has been authorized by the United States Environmental Protection Agency to regulate the injection of produced water into underground injection wells. Check out this illustration to learn more about co-produced saltwater disposal.

Vertical & Horizontal Drilling Combo 9:41

This animation details each step of the drilling and completion process using hydraulic fracturing for vertical wells and horizontal wells.

Need to catch up on the latest news?

The IPRB Blog has you covered!